There may be situations when you need to repeat your code / Looping. In SAP ABAP, statements are executed sequentially: The first statement in a function is executed first, followed by the second, and so on. Loop statements allow us to execute a statement or group of statements several times and the following is the general form of a loop statement in most programming languages.

The ABAP programming language provides 3 types of Loop statements such as:

- WHILE loop

- Do loop

- Nested loop

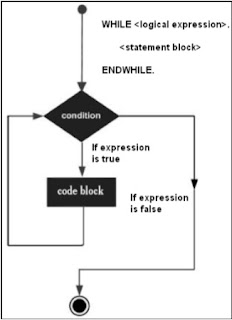

WHILE loop

WHILE loop statements repeatedly execute target statements as long as certain conditions are true.The general format of the WHILE command is as follows:

WHILE

.

ENDWHILE.

A block statement can be a single statement or a block statement. While Loop executes the statements attached by the WHILE and ENDWHILE commands until the logical expression becomes false.Example:

1

2

3

4

5

6

7

8

9

10

11

|

REPORT YS_SEP_15.

DATA: a type i.

a = 0.

WHILE a <> 8.

Write: / 'This is the line:', a.

a = a + 1.

|

The output is

This is the line: 0

This is the line: 1

This is the line: 2

This is the line: 3

This is the line: 4

This is the line: 5

This is the line: 6

This is the line: 7

Do loop

The unconditional loop repeatedly makes several statements without specifying any conditions. The DO statement applies the unconditional loop by executing a set of statement blocks several times without conditions.Syntax'Times' imposes restrictions on the number of loop paths, represented by 'n'. The value 'n' cannot be negative or zero. If zero or negative, the statement in the loop cannot be executed

Example:

1

2

3

4

5

6

7

|

Report YH_SEP_15.

Do 15 TIMES.

Write: / 'Hello'.

ENDDO.

|

The output is:

Hello

Hello

Hello

Hello

Hello

Hello

Hello

Hello

Hello

Hello

Hello

Hello

Hello

Hello

Hello

Nested loop

DO and WHILE statements can be tested and combined with other forms of loops. Each nested loop will have its own SY-INDEX which is created and monitored by the system.

DO [n TIMES].

.

DO [m TIMES].

.

ENDDO.

ENDDO.

Example:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

|

REPORT YS_SEP_15.

Data: a1 type I, b1 type I.

a1 = 0.

b1 = 0.

Do 2 times.

a1 = a1 + 1.

Write: /'Outer', a1.

Do 10 times.

b1 = b1 + 1.

Write: /'Inner', b1.

ENDDo.

ENDDo

|

The output is:

Outer 1

Inner 1

Inner 2

Inner 3

Inner 4

Inner 5

Inner 6

Inner 7

Inner 8

Inner 9

Inner 10

Outer 2

Inner 11

Inner 12

Inner 13

Inner 14

Inner 15

Inner 16

Inner 17

Inner 18

Inner 19

Inner 20

In this example, the outer DO loop is processed twice and the inner DO loop is processed 10 times, each time the outer DO loop is processed. So in this case, the inner loop is processed 20 times.